VetiGraph case study with Milano Pro Sport

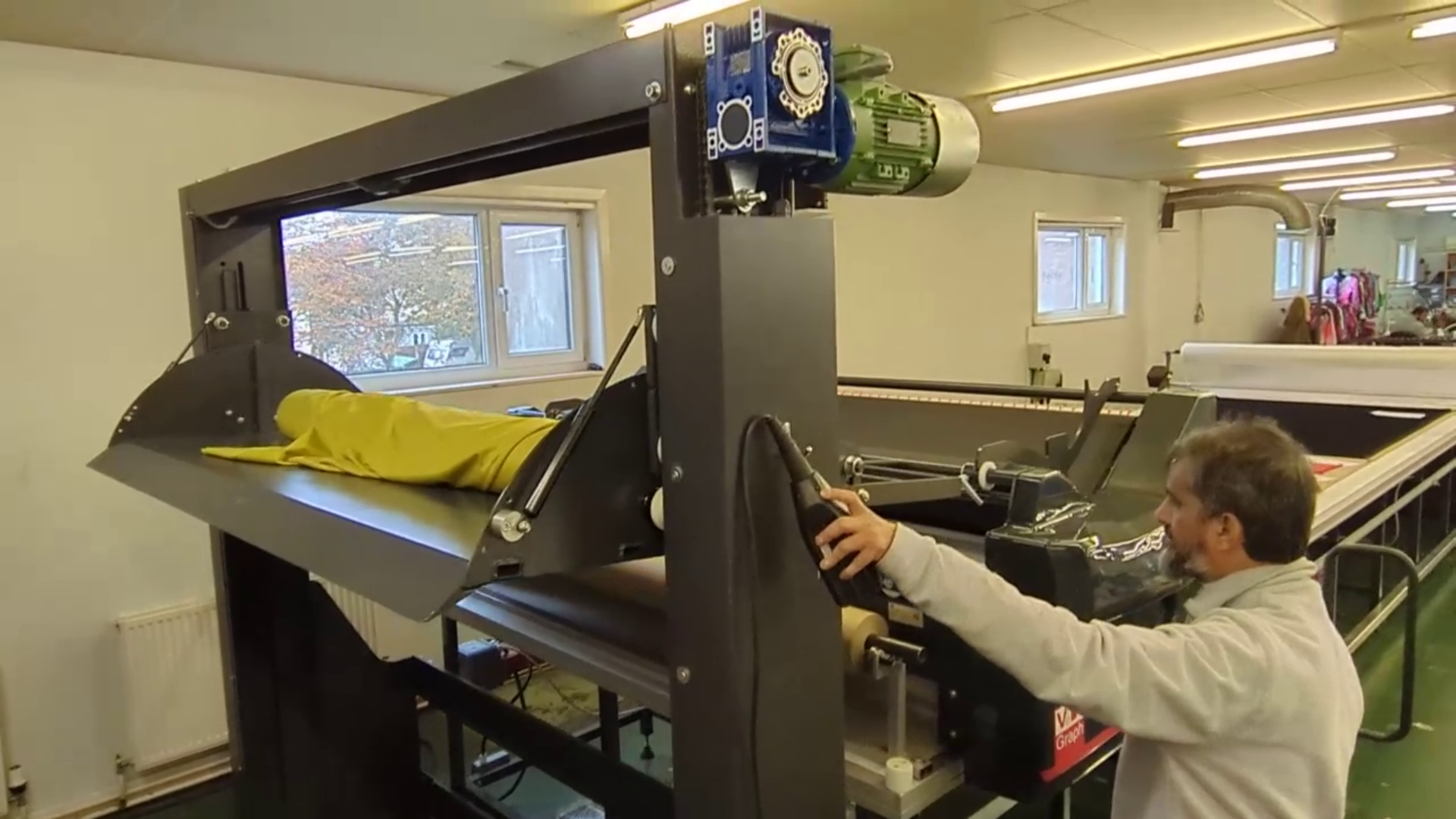

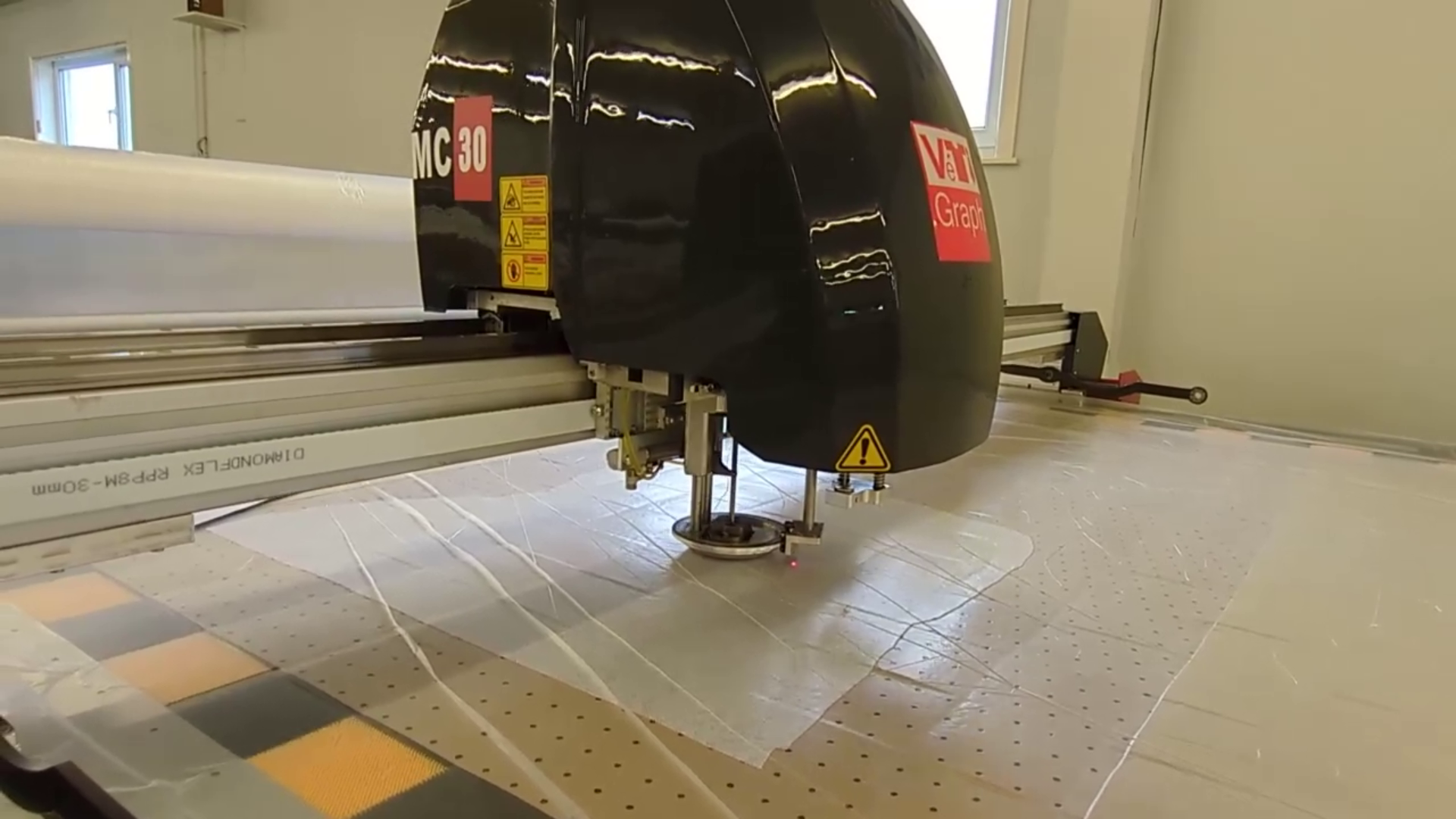

Milano PRO Sport is a manufacturer of gym wear and leotards based in Preston. The company recently invested in a new digital pattern cutting solution from Vetigraph to replace their aging CNC fabric cutter which struggled to design and cut the intricate panel details needed for their gymnastic wear.

We interviewed Mark Fryer, COO of Milano Sport in November 2023, asking him about UK manufacturing and what made Milano PRO Sport such a special company to work for.

Milano Pro Sport – Looking at the future of UK manufacturing

VetiGraph – What is your role at Milano?

Mark – I am the chief operating officer at Milano and I’ve been here for about 2 and half years as of yesterday, pretty exciting.

VetiGraph – So can you tell us a bit more about Milano?

Mark – Milano is a British manufacturer of sportswear; predominately we are gymnastics wear, that’s our main line. We are affiliated to a lot of the members of the sports like British gymnastics, international federations, the custodial of gymnastics.

VetiGraph – What is good about manufacturing in the UK?

Mark – It’s the standards: when we manufacture in the UK, the standards of our leotards and quality is controlled within our realm; we’re not importing something and hoping that it meets specifications. Gymnastics wear is nice and shiny but there’s a lot more technology that goes into it, it’s sportswear at the end of the day, it’s not fancy dress

There is a lot of prestige about UK manufacturing, and we are a proudly a member of Made in Britain. We are one of the last manufacturers of leotards in the UK and in Europe and all of our materials are sourced locally. Our labour force is local so we have total control from conceptualization of the design to the sample down to actually releasing it.

VetiGraph – What do you think you need to work efficiently in the UK?

Mark – You need a steady supply chain which is important and you need the labour. The UK is actually a good place to do the manufacturing which is very strange as everybody seems to think you have to go off shore to get it done: everything we need is basically on our doorstep.

Milano was purchased by a much larger organisation 4 years ago and we have since put massive investment into the business. The previous design and cutting room equipment was old and it wasn’t capable of growing as we’ve grown already in the last 2 years so it was time to put your hands in your pocket and start investing which is exactly what we’ve done with Vetigraph.

VetiGraph – What challenges do you foresee in the future for Milano?

Mark – Milano’s growth projector at the moment shows that we are doing very, very well. The challenges with any industry in the UK or Europe is obviously cheaper products coming in from the East. I don’t think that will ever change. That’s why we are proud to be British manufacturers, it comes down to a quality issue: leotards are high performance, high impact garments, so you don’t want cheap, you want quality. You are buying into the future.

VetiGraph – What’s the best thing about working at Milano?

Mark – I think it’s the ethos about the company: there’s something about the company, something about the industry. It’s one of those industries that opens your eyes and you start realising there is a big community out there and there is a love for the sport and Milano is paramount at the forefront of gymnastics. When people think of British gymnastics they think of Milano. The future is great and working at this company is the best job and the worst job I’ve ever had. The minute you wake up in the morning you want to come to work.

Visit Milano Pro Sport Website

Click to see a bigger image: