Single-Ply CNC Automated Fabric Cutters

In today’s marketplace customers increasingly demand highly customised products.

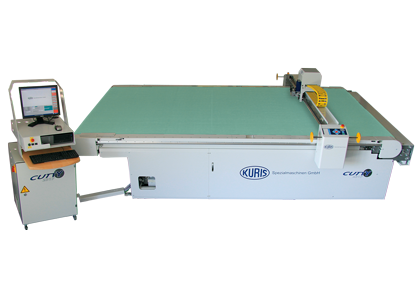

Single-ply cutters are ideal for cutting technical materials, cutting rooms with limited space, sample makers and short production runs.

VetiGraph are proud to be the UK agents for Kuris and GraphCut CNC Cutting Machines

Cost effective, advanced cutting solutions

The single-ply cutter is ideal for cutting single or low ply, offering the highest level of accuracy.

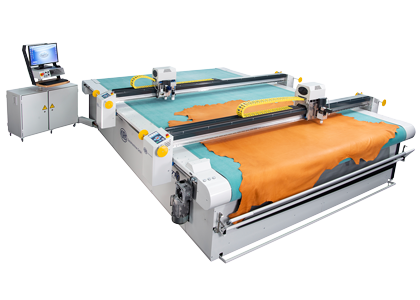

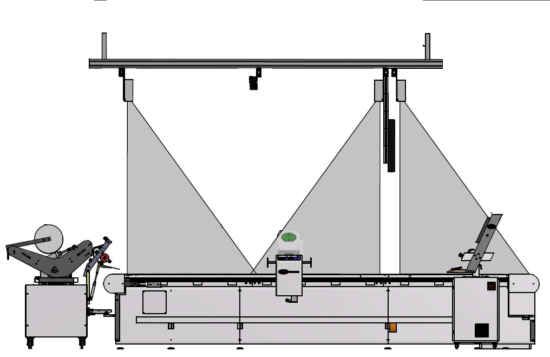

Single-ply machines are offered with a choice of either a static operation with a flatbed non-conveyorised table or a dynamic table including a conveyorised cutting and offloading area.

Both systems are user friendly, accommodate a range of tools for a variety of cutting applications, minimise fabric waste, cut to a high quality and reduce costs.

All our cutting machines are backed up with a comprehensive warranty package and UK based service and support.

KEY POINTS:

- Choice of static flatbed machine or dynamic machine equipped with a conveyor for continuous cutting.

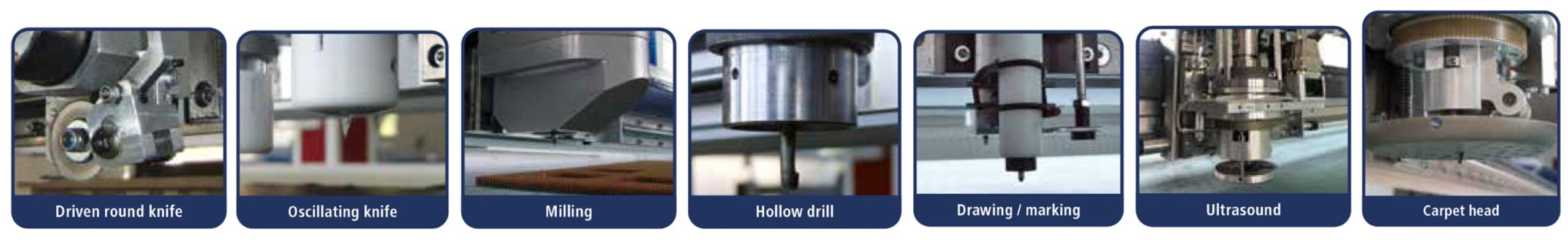

- Multi-tool cutting head including – Drawing – Drilling – Milling – Drag knife – Driven round knife – Oscillating knife (electrically powered) – POT knife (pneumatically powered) – Printhead.

- Built in vacuum to hold the material in place.

- Material thickness up to 20mm.

- Option of two bridges for independent cutting with two cutting heads in one. Cutting time saving: up to 40%.

- Fast interchangeable tools helping reduce setup times.

- File formats: DXF, HPGL, DMPL, CutFiles and others.

TECHNICAL DATA:

- Max. cutting height: 20 mm (depending on tool)

- Max. cutting speed: 90 m/min

- Max. positioning speed: 120 m/min

- Max. acceleration: 9 m/s²

- Nominal working widths (Y): 1,75 m / 2,15 m / 2,75 m

- Table widths: 2,30 m / 2,70 m / 3,30 m

- Nominal working lengths (X): 2,30 m / 3,50 m

- Total lengths: 3,80 m / 5,00 m

- Machine weight:1950 kg / 2300 kg / 3800 kg

- Working height: ab 0,85 m

MATERIALS:

A single-ply autocutter can be used to cut the following materials:

- Kevlar

- Rubber

- Carbon Fibre

- Glass Fibre

- Cotton

- Polyester

- Silk

- Dyneema

- Mylar

- Dacron

- Nylon

- Leather

- Canvas

- Cashmere

- Damask

and more…

INDUSTRIES:

A single-ply autocutter may be utilised in a variety of sectors, including:

- Automotive, Marine & Aircraft Interiors

- Military & Security

- Vehicle & Equipment Covers

- Awnings, Marquees & Tents

- Blinds & Curtains

- Carpets & Mats

- Composites

- Saddlery

- Bags & Luggage

- Digital Printers

- Insulation

- Inflatables

- Wet & Dry Suits

- Sail Makers

- Footwear

and more…

Our single-ply CNC cutting machines can utilise different cutting tools for different types of materials, providing the best and most precise processes for your production.

Leather Cutting

Our solution will digitally detect the outlines of the hide enabling the operator to view and accurately mark out the flaws on the hide to create quality zones. The patterns can be manually or automatically nested in the hide with priority parts allocated to each quality zone and the hide cut out either on-line or off-line.

Pattern Matching

We implement versatile solutions that will assist you with the most complex tasks when it comes to matching patterns to patterned fabric. VetiGraph will digitally capture the fabric motif, creating relationships between each piece. The nesting software will automatically nest the patterns to the highest yield and match the patterns perfectly to the fabric.

Contact us with your exact cutting machine requirements and we will happily:

- Quote you for the exact machine to meet your requirements.

- Arrange to video and test cut samples of your fabric.

- Arrange a live demonstration of a cutter in a working factory.

Made in the UK & Europe

All our Single-Ply cutting machines are made in the UK or Europe. This gives you the piece of mind of knowing that parts are not located the other side of the world.

Our engineers are factory trained, based in Leicester, and cover the whole of the UK.

Fashion & Apparel

Furniture & Upholstery