Photo Digitisers & Scanners

ScanGraph digitising solutions will improve your design productivity by digitising batches of hard copy patterns or templates fast and accurately. Using our photo digitisers and digitisation scanners, you can streamline your pattern creation process and ensure precision.

Do you want to make your legacy patterns or templates digital?

From low tech to high tech in a few simple steps

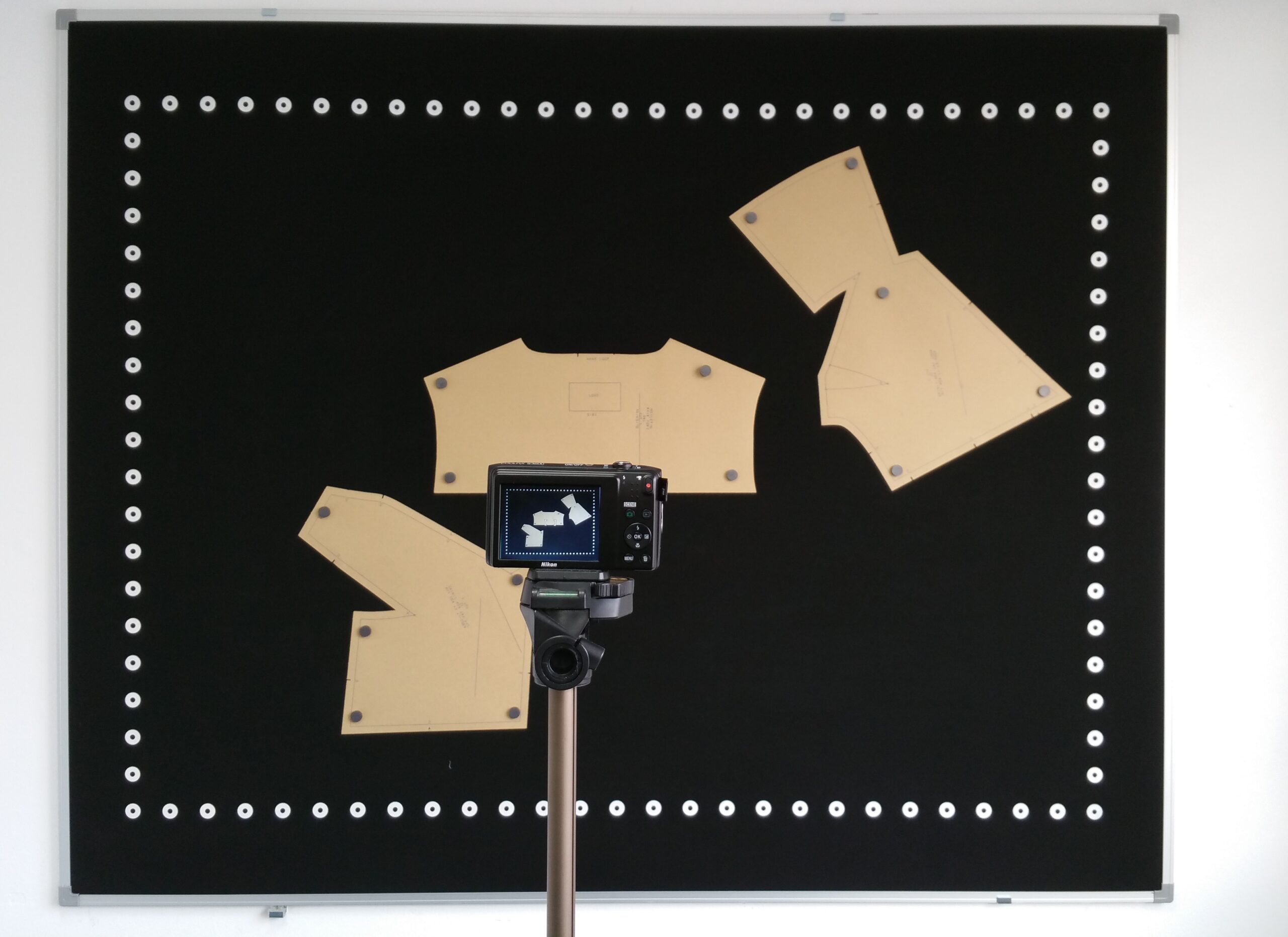

ScanGraph Photo Digitiser – The new approach to Digitising patterns

ScanGraph photo digitising enables you to quickly and accurately capture patterns. This system is perfectly suited to inputting patterns and templates made from a wide variety of materials including card, fabric, metal, vinyl, plastic, or plywood. This photo digitiser converts images from JPEG to digital pattern files using an ordinary digital camera.

The system is highly accurate, using a calibrated digitiser board (standard size 150 x 120cm) and a camera phone to input your full sets of templates including outlines, seam allowance, internal lines, and markings.

This affordable and versatile solution enables the digitising of parts of any size: from very small product patterns such as personal leather goods or car mats to templates for sofas or large parts for the composite and automotive industry.

ScanGraph A0 Vertical Digitisation Scanners

If time is of the essence or you have a large back catalogue of legacy patterns to scan, then our A0 Vertical Scanner is the solution.

When used with the upright scanner, the patterns are placed into a transparent plastic wallet and fed into the scanner. The wallet allows the operator to scan multiple lightweight and/or odd shaped originals at one time. The process takes seconds and produces highly accurate results.

The system immediately recognises the outlines of any pattern, and its internal lines, as well as any angles, notches, drill holes etc. It offers a high level of precision, and a range of functions.

After digital pattern creation

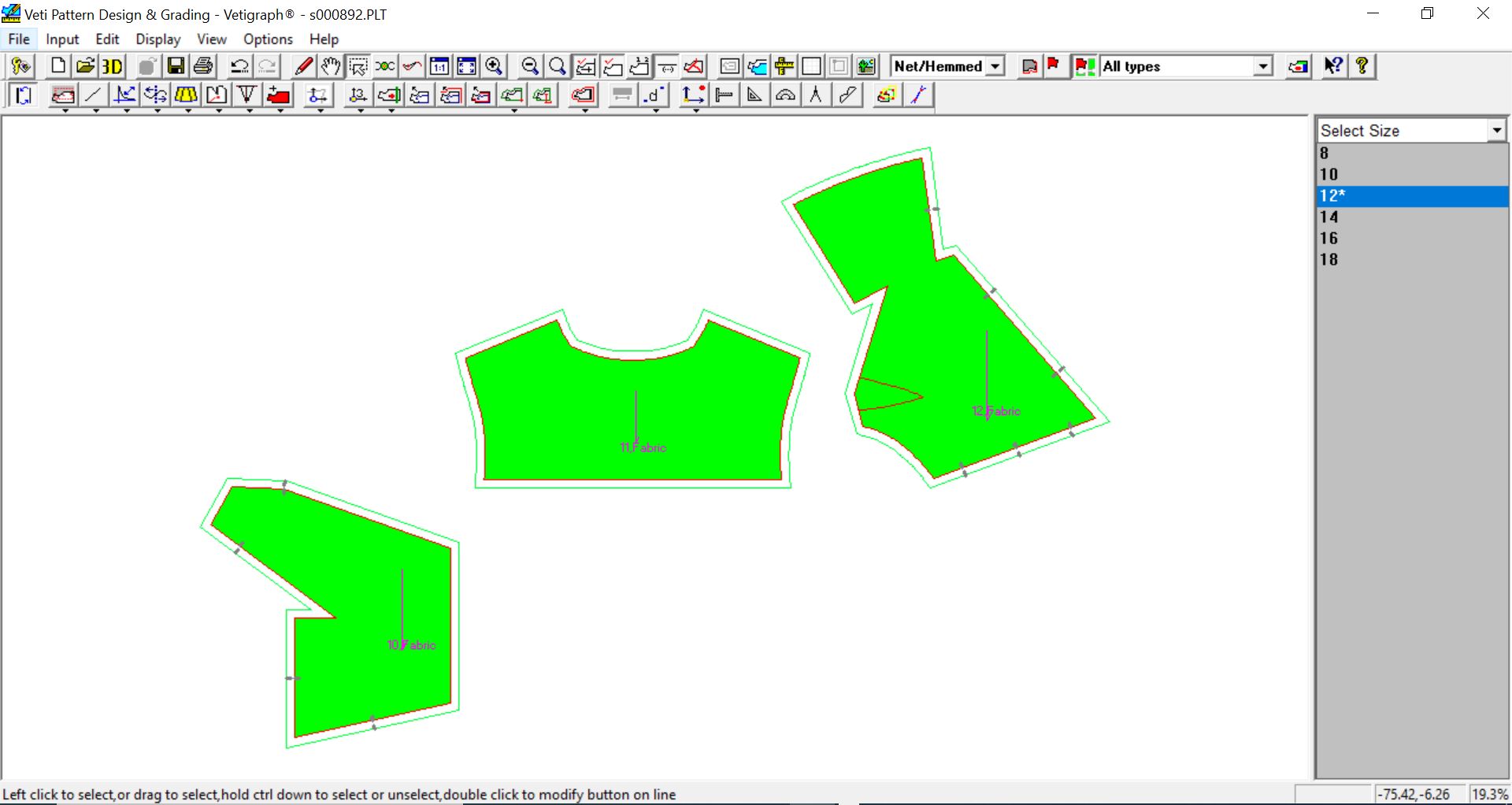

The user can name the individual pieces, establish cut quantities, place pieces on the fold, set the grain direction etc. “Clean”, “Edit” and “Text” functions enable the user to modify the scanned image if required and add annotations.

Patterns are opened directly into VetiGraph software and are ready to be checked, amendments can be made where necessary and then lay planned to determine fabric consumption. The patterns can be taken through VetiGraph’s automated grading process if necessary.

Don’t worry if your patterns are of poor quality as the software offers a range of tools enabling you to amend and rectify areas which are worn out and damaged.

Our solutions allow you to input templates which may widely vary in size.

Plotter Printers

Whether you are a design studio or manufacturing business it is essential to have a plotter that is reliable, up to the job in hand and within budget.

Find out more:

Fashion & Apparel

Furniture & Upholstery