In the fast-evolving world of manufacturing and design, professionals across the UK are continuously seeking innovative solutions to enhance efficiency, precision, and productivity. At the heart of this technological revolution is CAD/CAM — two acronyms that have reshaped industries far and wide.

But what exactly is CAD/CAM, and why has it become such a pivotal tool for professionals in various sectors?

Understanding CAD/CAM

CAD/CAM stands for Computer-Aided Design and Computer-Aided Manufacturing. At its core, CAD refers to the use of computer software to create detailed designs, while CAM involves the use of computers to control manufacturing processes, such as machining and fabrication. Together, CAD/CAM systems integrate design and manufacturing functions, allowing for seamless communication and collaboration between designers and production teams.

Contents

The Evolution of CAD/CAM

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) can be considered “siblings” in the world of digital technology, each serving a critical role in the lifecycle of a product. CAD software is used to create precise drawings and technical illustrations of products, while CAM software takes these designs and translates them into instructions for manufacturing machinery.

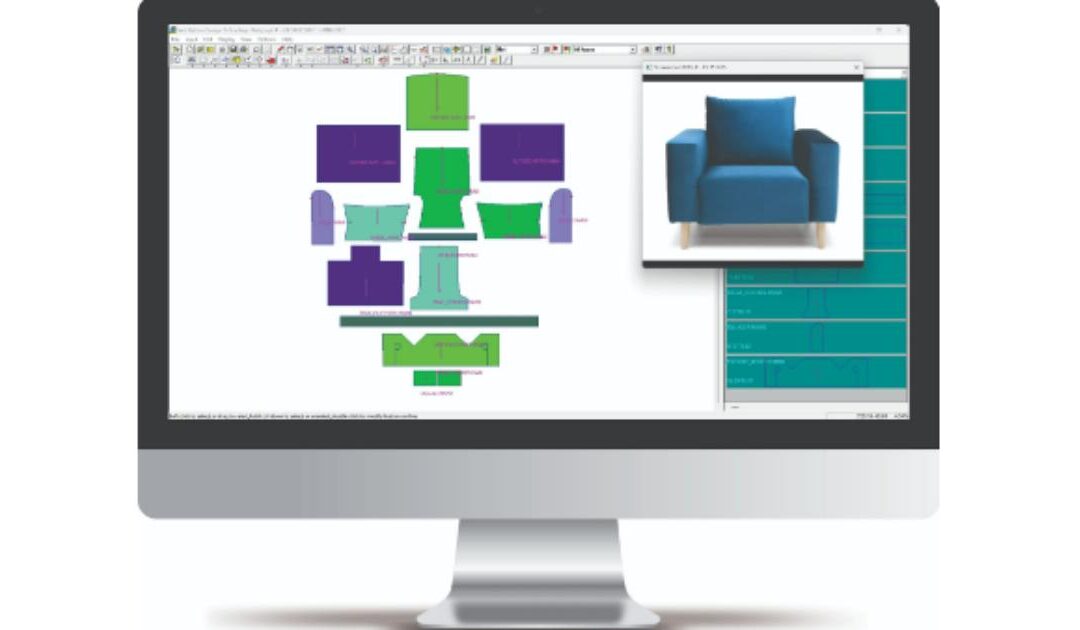

The integration of CAD/CAM systems marks a significant leap from traditional design and manufacturing methods, offering unparalleled speed, accuracy, and flexibility. From furniture to fashion design, CAD/CAM technologies are the backbone of modern production processes.

The Power of CAD

Computer-aided design (CAD) software represents the first step in the digital design-manufacturing pipeline. Professionals use CAD tools to draft and model objects with an extraordinary level of detail, impossible to achieve manually. This software enables designers to experiment with different materials, structures, and aesthetics virtually before any physical prototype is produced.

Sectors like automotive seating, furniture and upholstery, and many other design sectors have been revolutionised by CAD technology. Designers can create detailed 3D renders, simulating real-world conditions, materials and even body sizes and shapes. CAD not only accelerates the design process but also significantly reduces errors, ensuring that the final product meets or exceeds expectations.

The Role of CAM

Once a design is finalised in CAD software, Computer-aided manufacturing (CAM) comes into play. CAM software uses the detailed designs created by CAD to control machinery and equipment during the manufacturing process. This includes machines like CNC cutters (Computer Numerical Control) fabric cutters.

CAM technology allows for the automated production of items directly from CAD models, minimising human error and enhancing production efficiency. In industries where precision is paramount CAM’s impact cannot be overstated. It ensures that each part is manufactured with exact adherence to design specifications, crucial for the functionality and safety of high-stakes products.

The Synergy Between CAD and CAM

The true magic happens when CAD and CAM systems work in unison. This synergy streamlines the transition from conception to production, allowing for a seamless flow of information and a unified workflow. For professionals, this integration means faster turnaround times, cost savings, and the ability to rapidly iterate on designs based on real-world testing and feedback.

Furthermore, CAD/CAM integration is vital for custom and bespoke manufacturing. In a market that increasingly values personalisation—from tailor-made clothing to custom automotive seats—CAD/CAM technologies provide the flexibility to meet unique customer demands without compromising on efficiency.

Advancements and Future Directions

With the UK at the forefront of engineering and technological advancements, the evolution of CAD/CAM technologies continues at a brisk pace. Cloud-based CAD/CAM solutions are gaining traction, offering greater collaboration opportunities across global teams and facilitating the sharing of large design files with ease.

Artificial intelligence (AI) and machine learning are also beginning to influence CAD/CAM systems, with software capable of suggesting design improvements, optimising manufacturing processes, and even predicting potential faults or failures before they occur.

Sustainability is another area where CAD/CAM is making its mark. By optimising designs for material efficiency and streamlining production processes, these technologies are helping companies reduce waste and minimise their environmental footprint—a growing concern for both businesses and consumers in the UK.

Revolutionising Design and Manufacturing with CAD/CAM

CAD/CAM technologies represent a nexus of innovation, efficiency, and creativity in the design and manufacturing landscape. By transforming how products are designed and manufactured, these tools are not just shaping industries; they’re redefining what’s possible.

As we look to the future, the continued evolution of CAD/CAM will undoubtedly bring even more sophisticated solutions to complex design and manufacturing challenges. For professionals who are willing to harness these technologies, the opportunities are as boundless as their ambitions.

For those ready to take their projects and careers to the next level, the message is clear: the future belongs to those who can blend creativity with cutting-edge technology. And in the realm of CAD/CAM, the future is now.

Are you looking to stay ahead in the fast-paced world of design and manufacturing? Explore the potential of CAD/CAM technologies with Vetigraph today and join the vanguard of innovation shaping tomorrow.